Dixon On-Site Safety Training

In partnership with our distributors, Dixon offers no-cost on-site safety training at your plant. Plant safety is an ongoing endeavor in which it is impossible to be an expert in every field. The use of damaged or misapplied hose couplings and accessories sometimes occurs, and, to the untrained eye, may continue to exist until an accident happens, threatening plant personnel and equipment. For more information, please contact Dixon at 800.355.1991.

Our program includes:

- A visual inspection by Dixon technicians of your hose assemblies and accessories

- A confidential report containing Dixon's observations and recommendations for corrective action

- A follow-up program offering a hands-on seminar relating to your safety concerns

Common Assembly and Application Concerns:

Missing Safety Clips

The use of a safety type retainer is necessary to ensure that the universal couplings will not accidentally disconnect.

In-line Clamps

The band clamp buckles should be offset to eliminate straight line leaks.

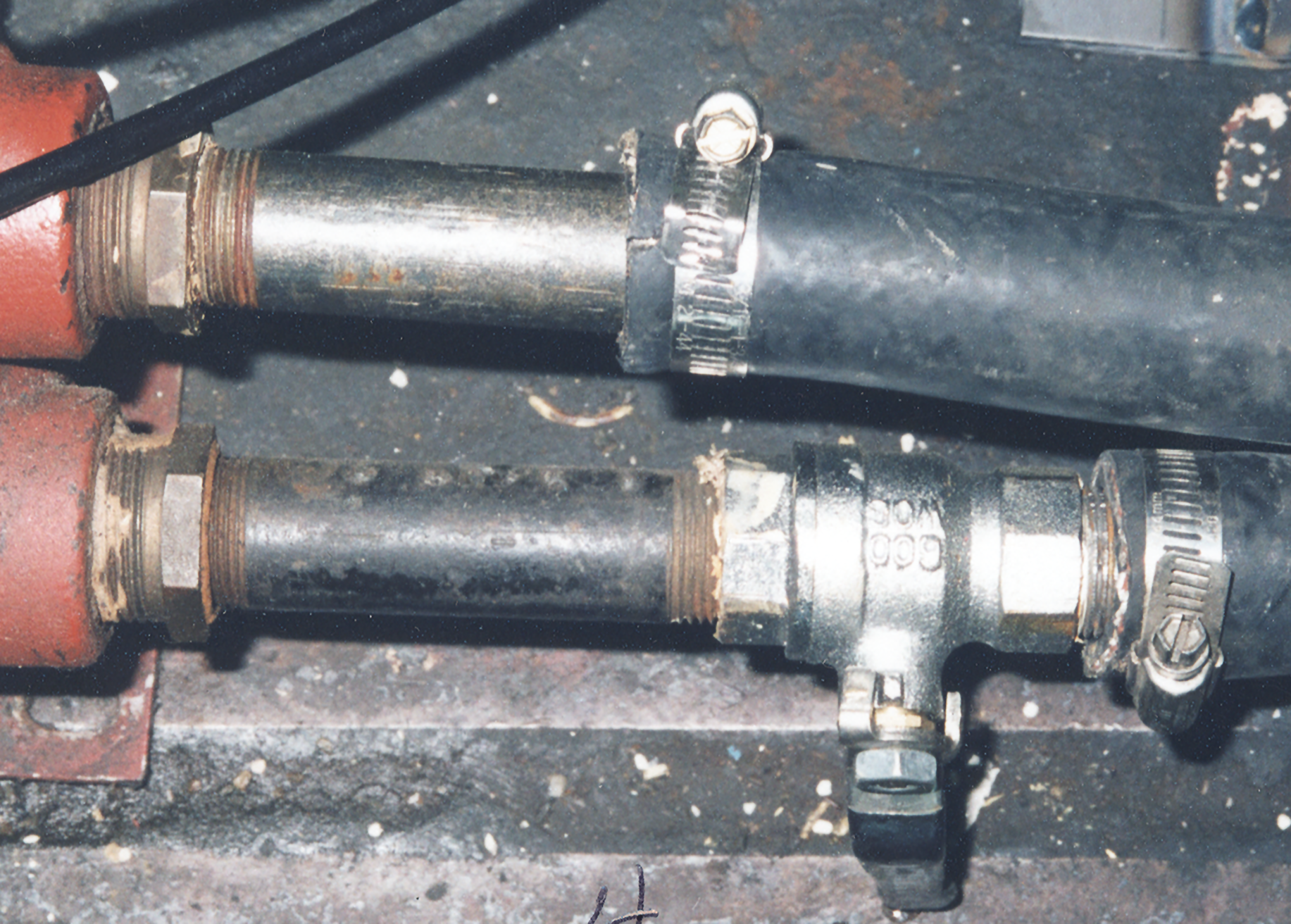

Common Pipe Nipples

Industrial hose should be coupled with the properly barbed or serrated hose stems.

Missing Bolts on Clamps

The bolts supplied with the clamps are an integral component of the overall usability and proper function of the clamp.

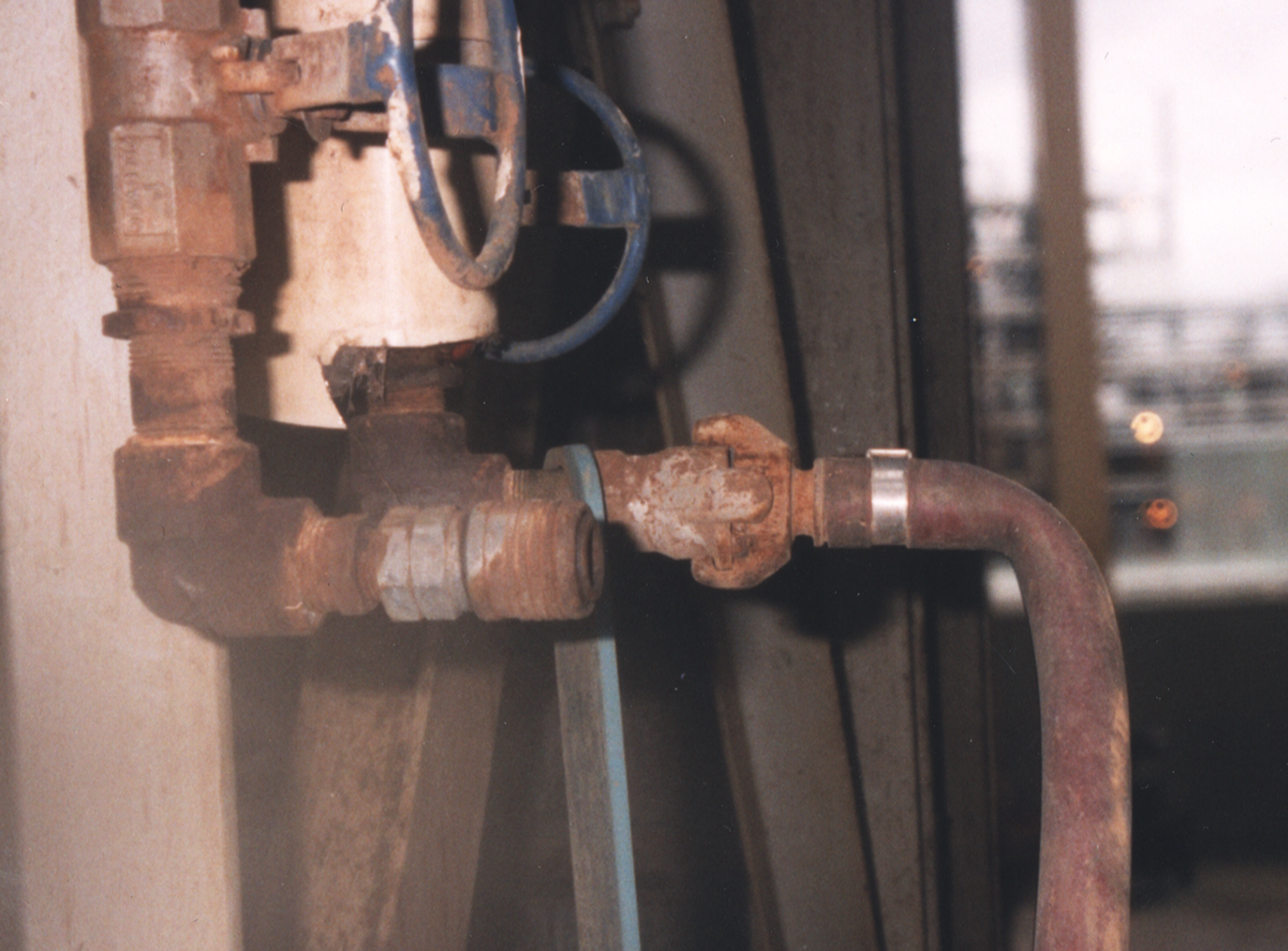

Horizontal Outlets

A hard piped outlet horizontal to the floor is very dangerous, inefficient, and causes undue stress on the hose.

Dust Plug Usage

The use of dust plugs keeps contaminants out of lines, prevents environmental damage, and keeps gaskets properly in place.

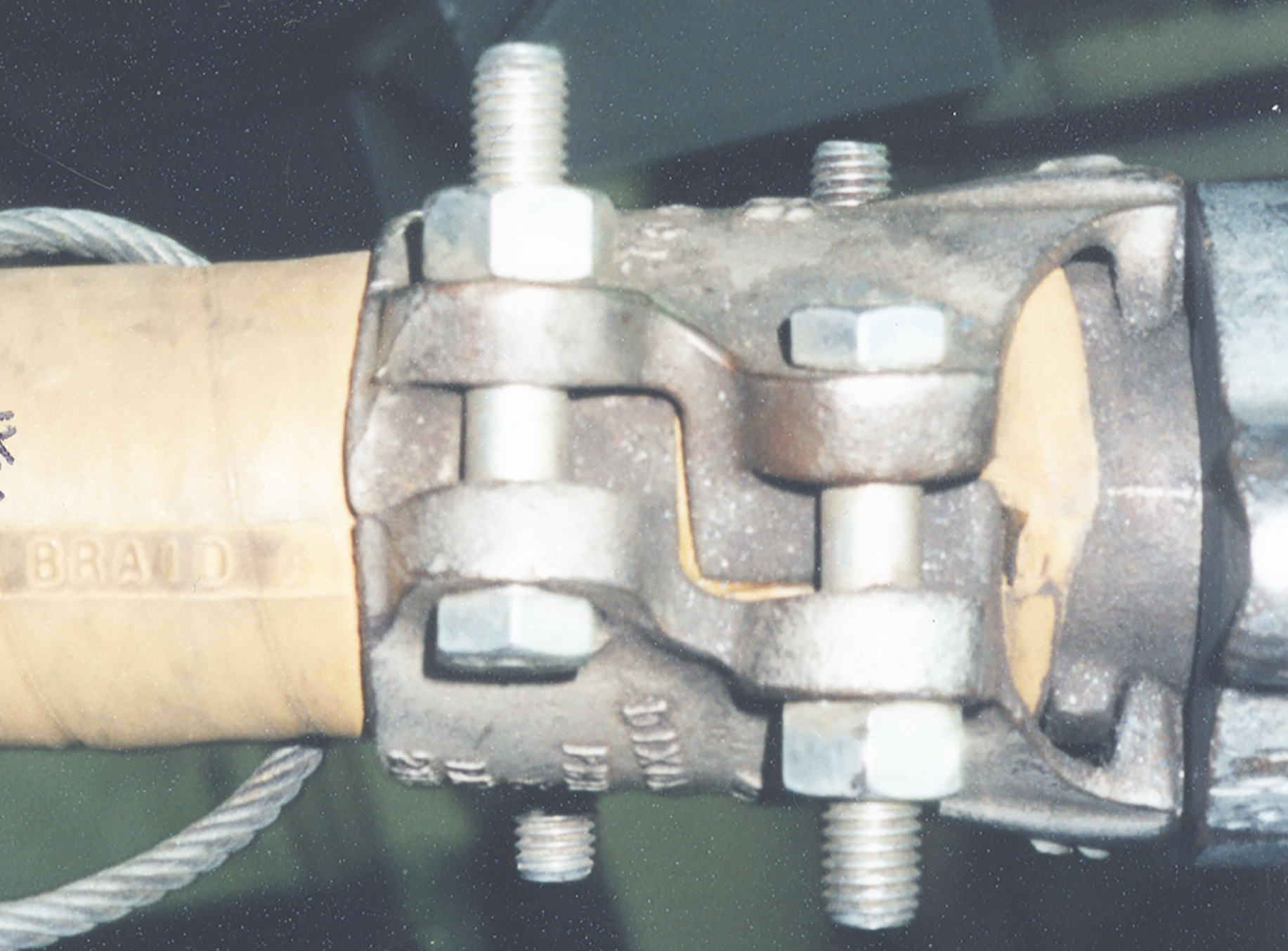

Clamps Are Bottomed-Out

Individual body sections of bolt style clamps should never be allowed to come in contact with each other.